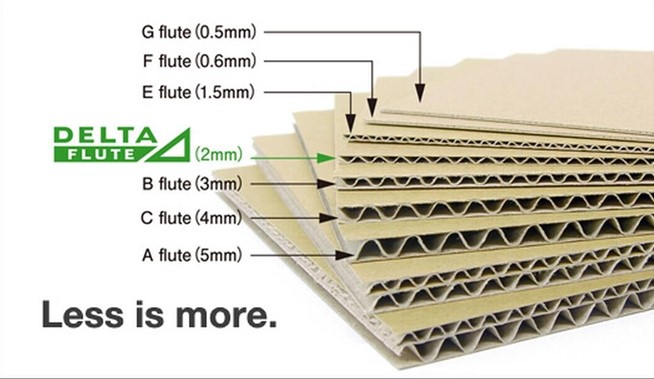

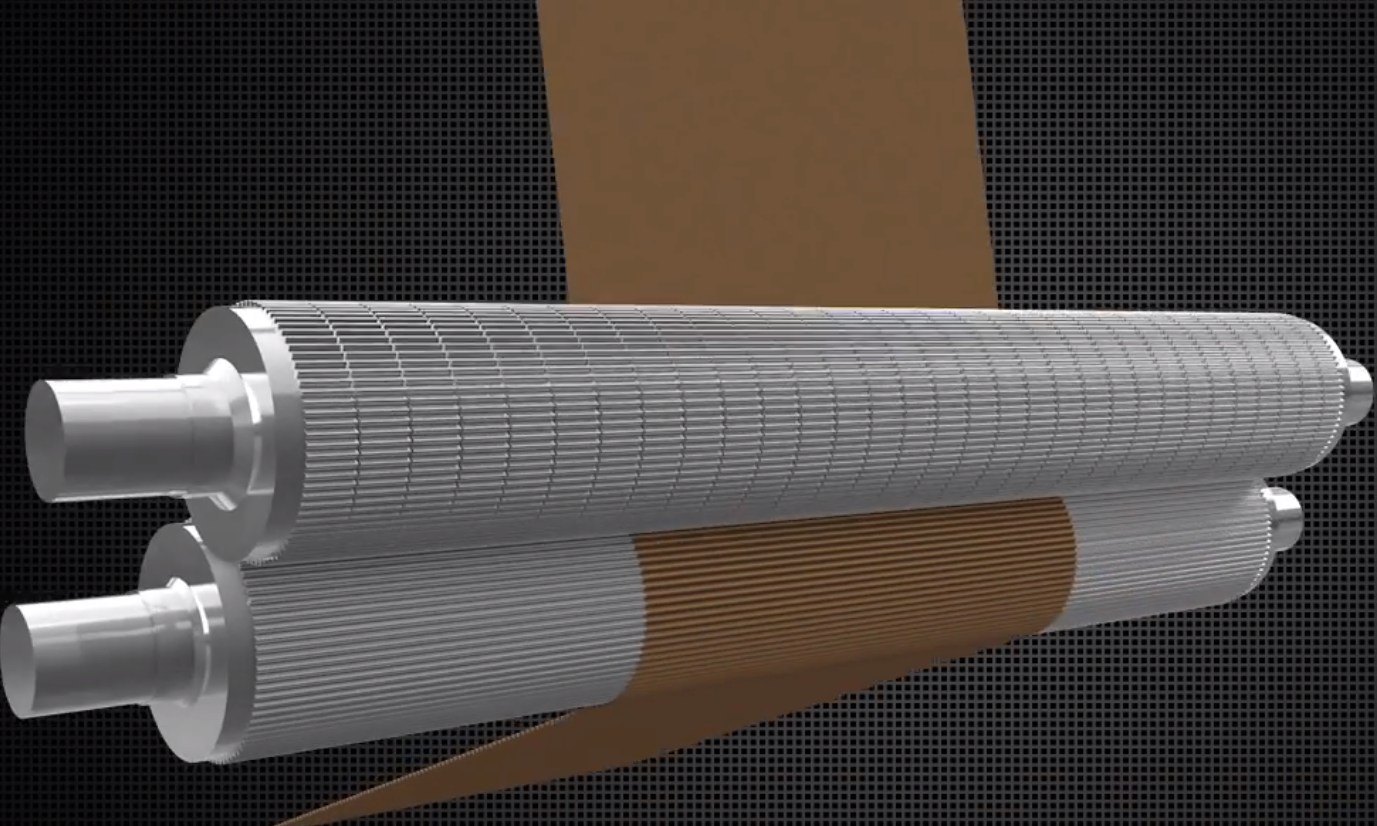

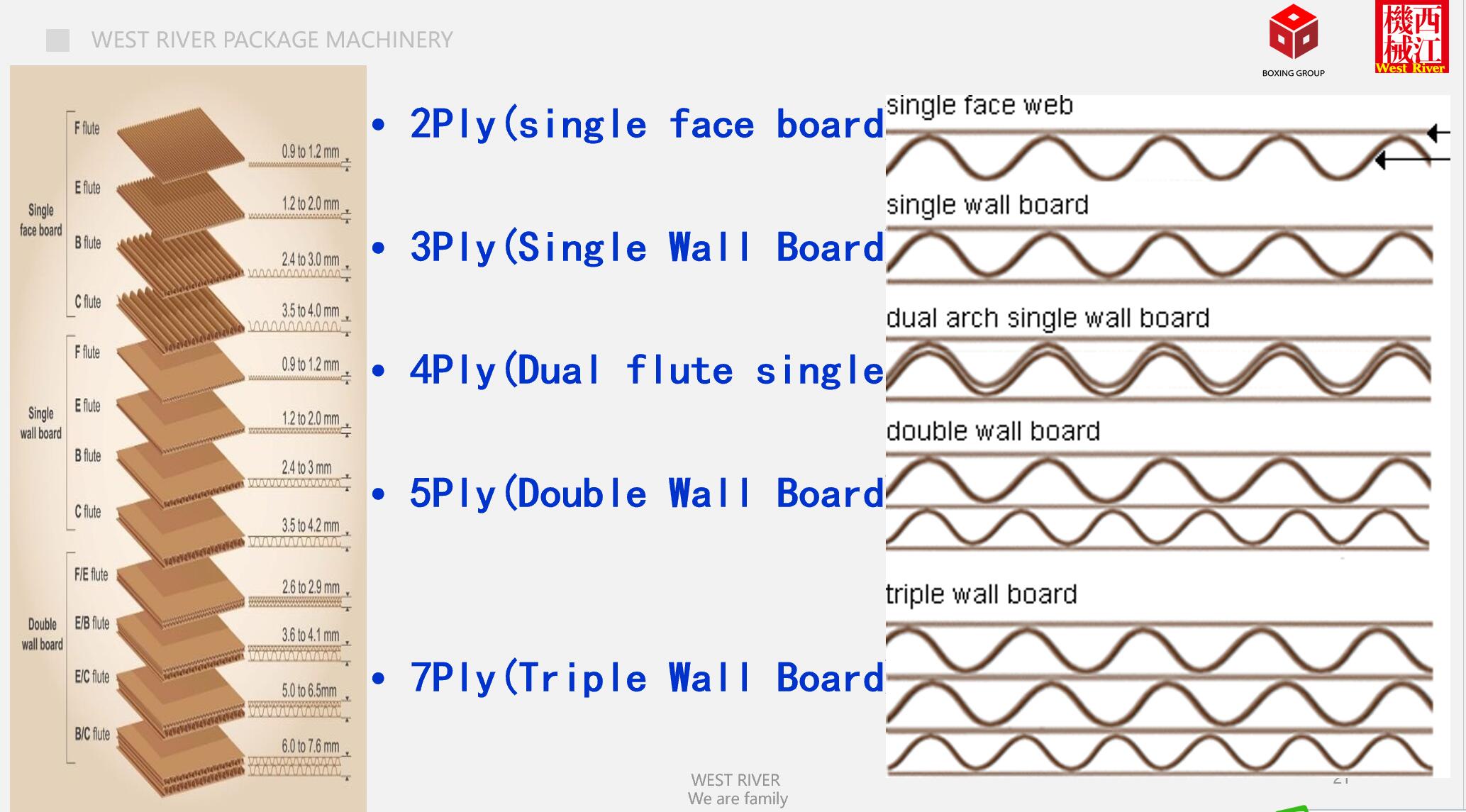

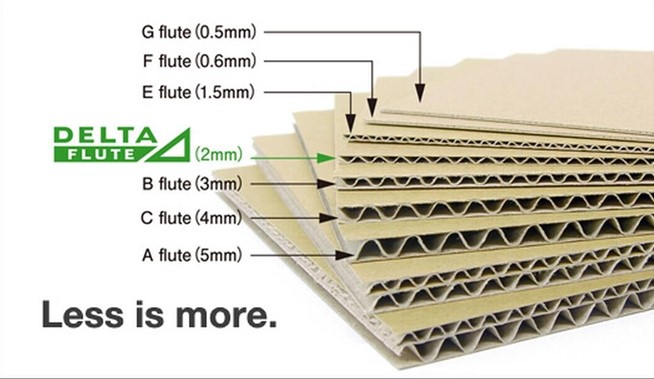

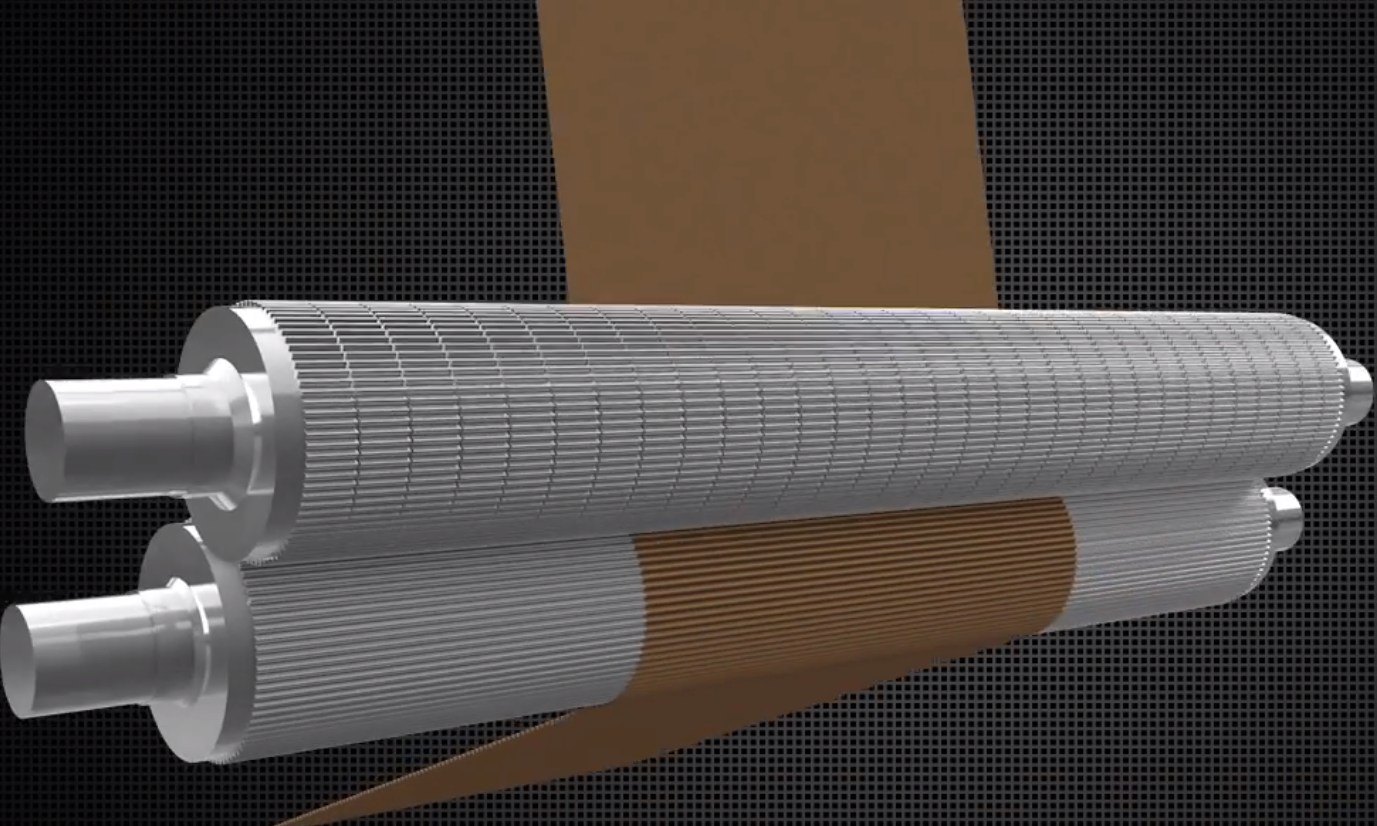

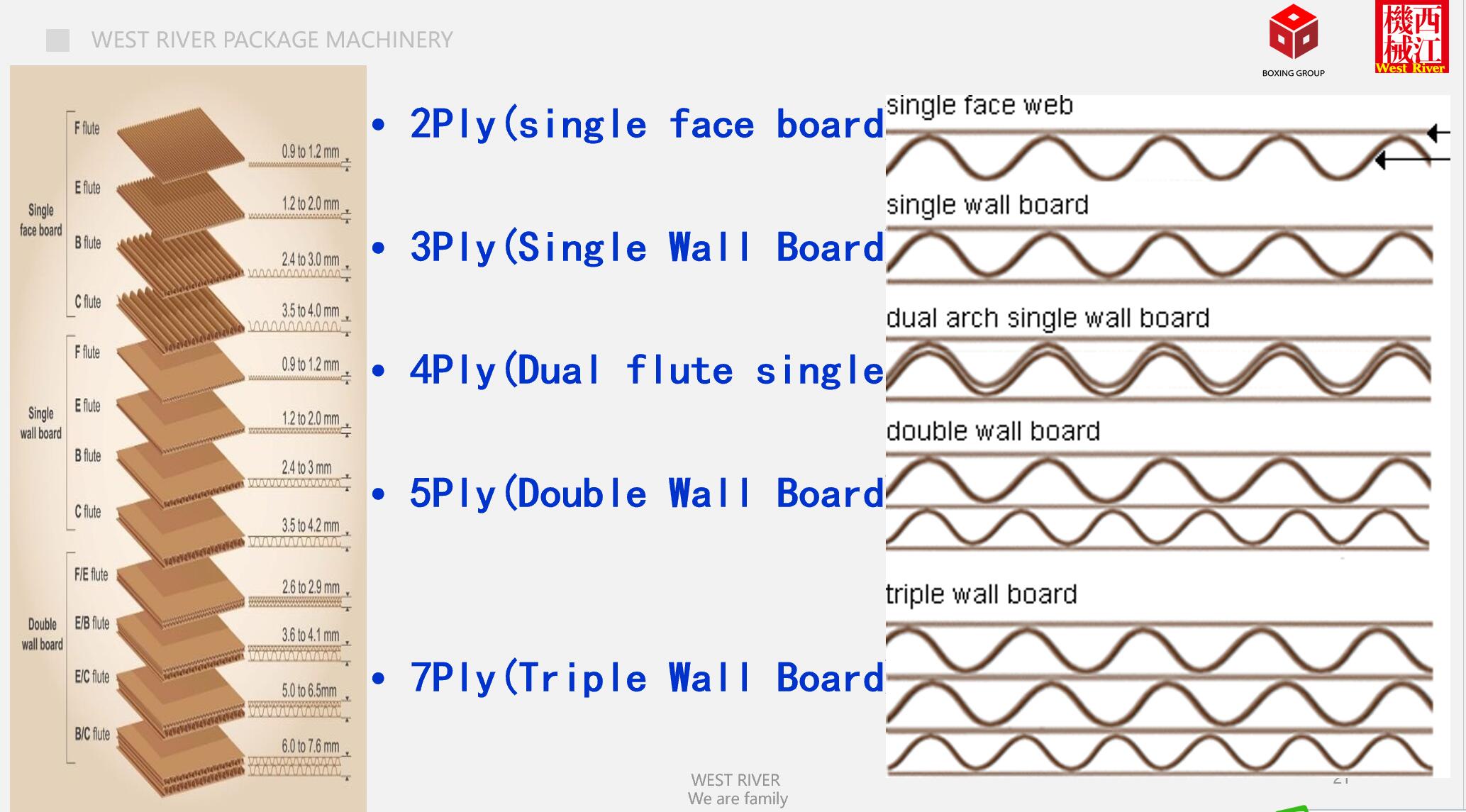

Many users easily ignore the shape design, quantity and tooth design of flutes when choosing corrugated cardboard manufacturing equipment, because it is directly related to the strength of the cardboard and the length of paper. It is also related to the cost of starch and the manufacturing of corrugated cardboard. WEST RIVER's comprehensive technology can help customers accurately realize high-precision corrugating roller design and manufacturing to achieve low-cost and high-quality cardboard production.

Flute Type and technical parameter |

Flute | Height(mm) | Teeth Quantity/300mm | Take up factors | Remark |

A | 4.6~4.9 | 34±2 | 1.5-1.56 | UV shape |

C | 3.6~3.9 | 38±2 | 1.4-1.49 | UV shape |

BC | 3.2-3.3 | 44±2 | 1.38-1.47 | UV shape |

B | 2.6-2.9 | 50±2 | 1.35-1.42 | UV shape |

D | 2.0-2.2 | 78±4 | 1.35-1.40 | UV shape |

E | 1.5-1.8 | 88±2 | 1.30-1.38 | Might make UV to V shape according to the requirement of the clients |

1.1-1.5 | 92±2 | 1.25-1.33 |

|

F | 0.8-1.0 | 128±2 | 1.22-1.28 |

|