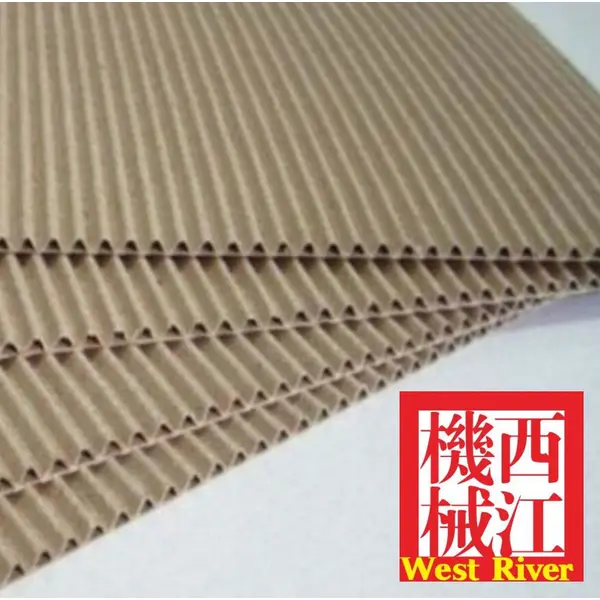

A 2-ply single face corrugated cardboard production line is a manufacturing system that produces corrugated cardboard with two layers of craft paper, it is mainly used for 2ply package or lamination into 3ply offset carton box.

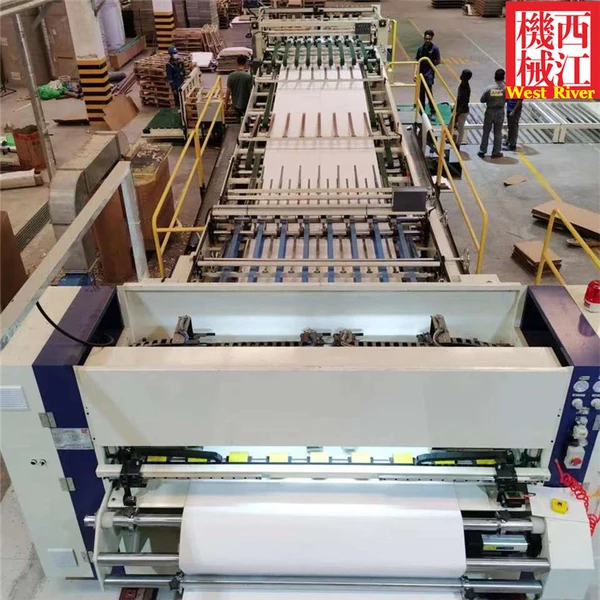

The production line typically consists of several machines and processes, including:

1. Single facer Corrugator: This machine is the heart of the production line and is used to create the single face corrugated cardboard. It has corrugated roller(hard chorme or tungsten carbide) to wave the craft paper, and other heated rollers that apply heat and moisture to the paper. The corrugator also glues the two layers of paper together.

2. Mill roll stands: These machines hold large rolls of paper material and feed to the single facer machine for corrugation, which are unwound and fed into the corrugator.

3. Glue station: This is where glue is made and is applied to the corrugated medium, which is the wavy layer of paper that provides strength and rigidity to the cardboard.

4. Preheatesr: This machine heats the paper before it enters the corrugator, allowing for better adhesion of the glue.

5.NC computer control Sheeter: This machine cuts the corrugated cardboard into the desired width and length with scores for option. It is controlled by conputerized system to cut in different order and automatically change in different order.

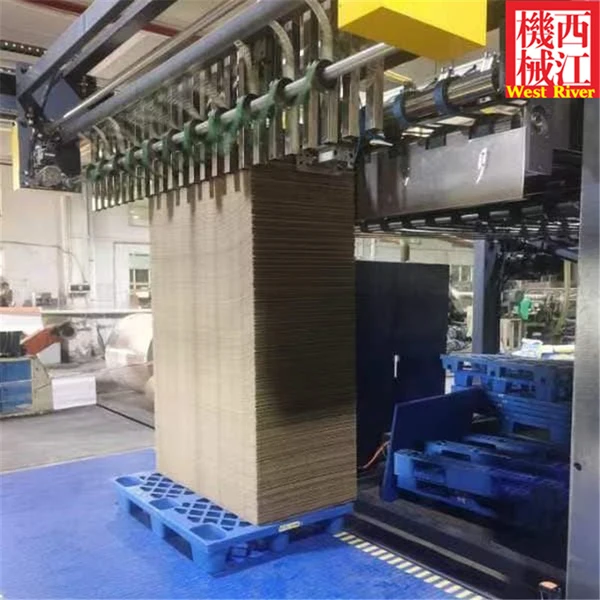

6. Stacker: This machine stacks the finished corrugated cardboard sheets or boxes in a neat and organized manner for easy handling and transportation. West River provides down stacker or swing stacker for customer's option.

The production line is typically automated, with computerized controls and sensors to ensure precise and efficient operation. It can produce corrugated cardboard in various sizes and shapes, depending on the specific requirements of the customers.

WEST RIVER Fully auto 2Ply corrugated cardboard production line:

Design width: 1200-2500mm

Design Speed: 100-220m/min

realize best quality high strength cardboard for production

WEST RIVER Corrugated Machinery Co. is a leading manufacturer of complete corrugators ranging from 1200-3000mm in width and speeds from 100-350m/min. Established in 1954, the company has a rich history of 70 years in the industry and has accumulated extensive mechanical engineer experience.

As pioneers in the field, WEST RIVER was the first company to manufacture corrugated machines in China and played a significant role in establishing the Chinese national corrugated standard. This demonstrates the company's commitment to quality and expertise in the industry.

Support and Services:

We provide technical support and services for our users to ensure its smooth operation and optimal performance of their machines. Our technical support team is available 7*24 to answer any questions or provide assistance. Our services include:

Consulting of machines

Customized design solution,

Installation and setup of the machine

Troubleshooting and diagnostics

User training and support

FAQ:

Q1.What is the brand name of the machines?

A1.The brand name of the machines is WEST RIVER. It is a well know brand starts from 1954.

Q2.What is the model number of the machines?

A2.The model number of the machines is DWJ-.

Q3.Where is the WEST RIVER factory located in?

A3.The WEST RIVER factory is located in south of China in Zhaoqing city, near to Guangzhou about 1 hours by car.

Q4.What certifications does the WEST RIVER have?

A4.The WEST RIVER has SGS CE and ISO9001 certifications for their products.