Main datas:

Max gluing speed | 200m/min |

Max feeding size | 2850 x 1200mm |

Min feeding size | 600 x 300mm |

Folding mode | Top folding |

Available sheet | 3 layers, 5layers |

Total power | 15kw |

Voltage | 380V, 50HZ, 3Phase |

Dimension | 12500 x 3200 x1600 mm |

Description & Feature:

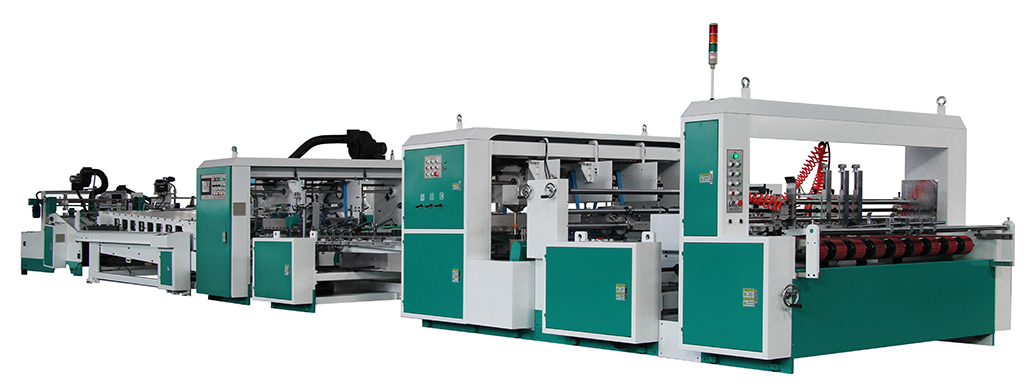

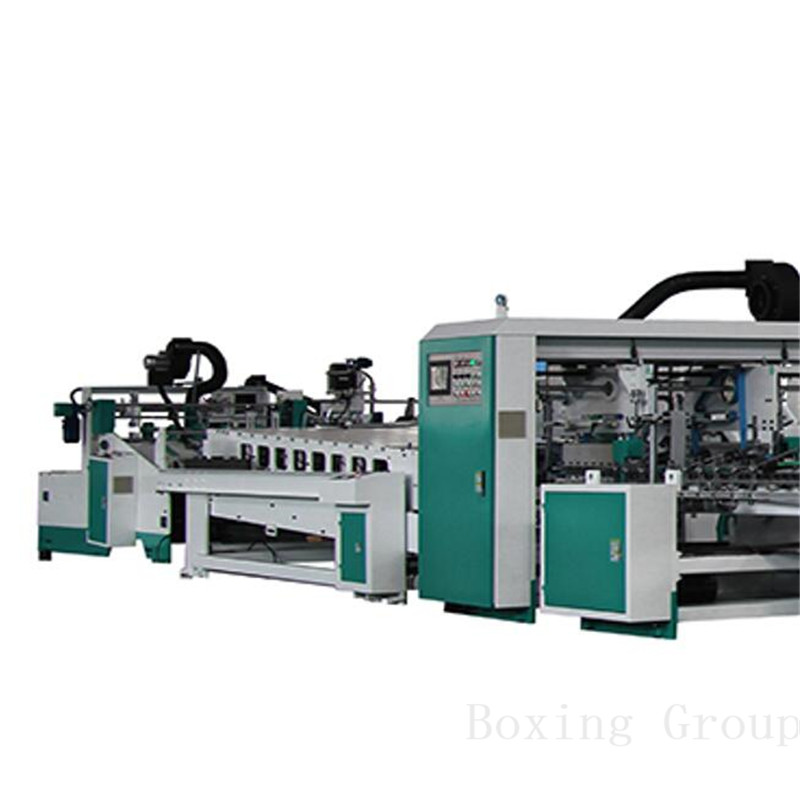

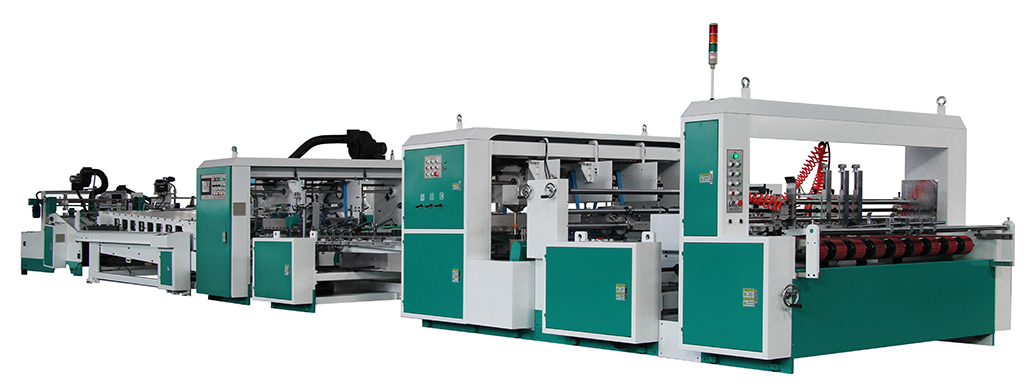

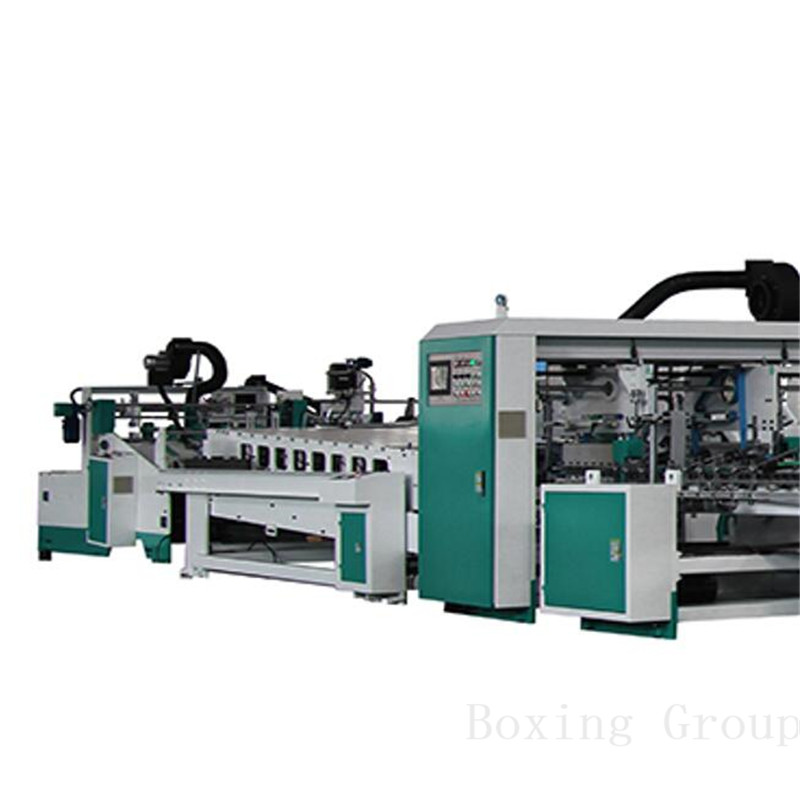

² Automatic folder glue machine consist of three sections: vacuum feeding section, gluing & folding section, counter & stacker section.

² All motors except frequency conversion motor adopt Taiwan CPG motor. Frequency conversion motor with quality inverter adjust speed. PLC and touch screen control system for easy operation and running stable. Energy conservation and high speed, saving labor cost.

Ⅰ、Feeding unit

Ø Vacuum suction feeding to feed warping paperboard easily.

Ø Qualit electromagnetic clutch and brake adpoted,feeding section controlled independently,operation easily.

Ø Stainless steel glue wheel adopted,long life saving glue cost.

Ø Second creasing struction can impress again the paperboard which was not creased well.

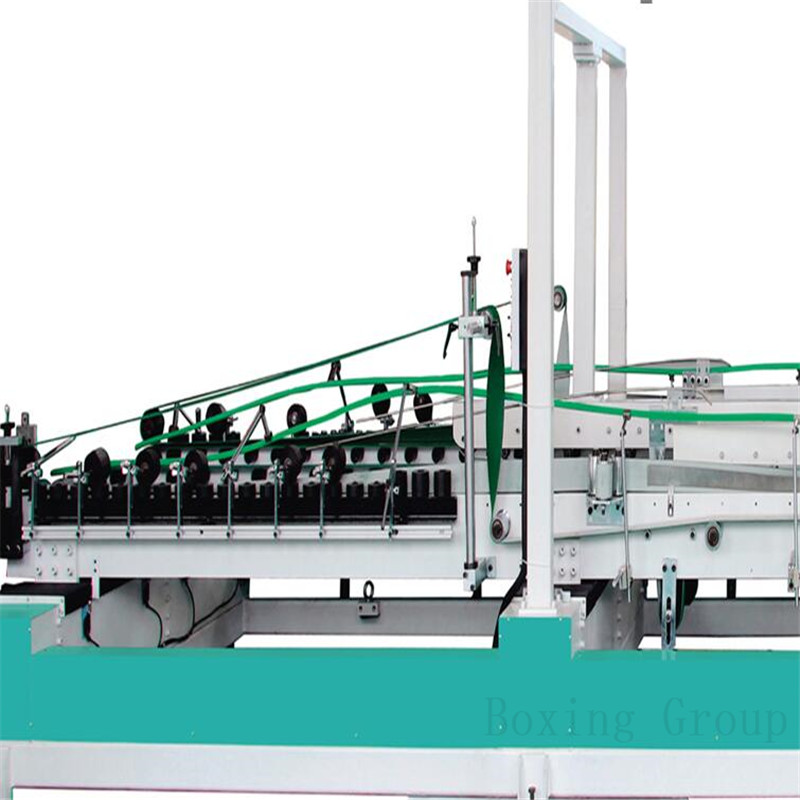

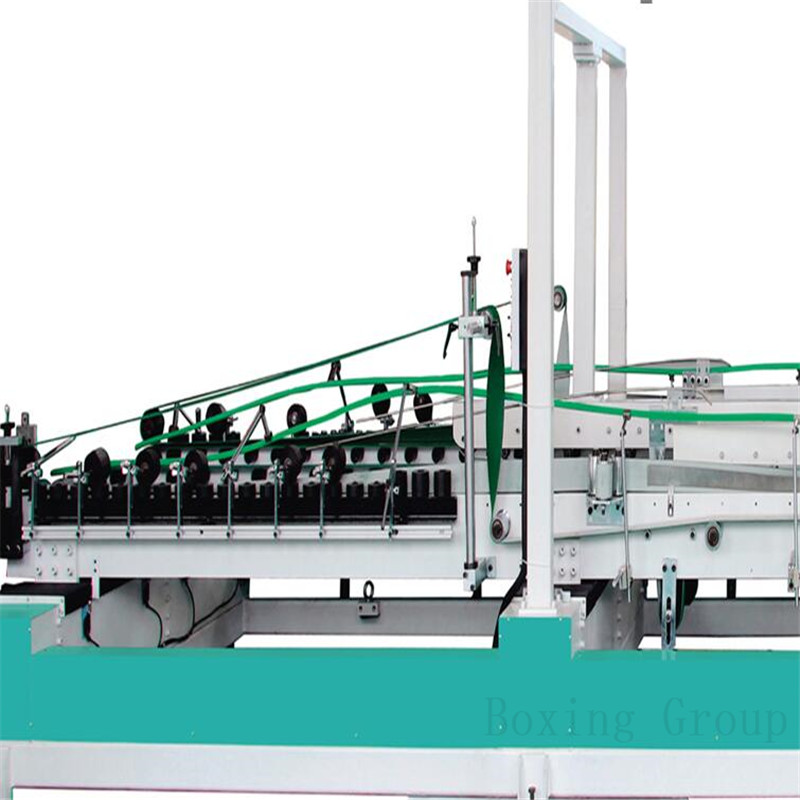

Ⅱ、Glue&Folding unit

Ø The biggest feature of the folding section is that it is equipped with a rolling line failure wheel to carry out secondary rolling and re-roll the original rlling line. This makes the cartons more aesthetically folded. There will be a shaping device in front of the nailing box behind the folding part, and the folded carton will be shaped again before the nailing box, to ensure that the nailling out of the carton without scissors mouth.

Ø Simpless structure and high reliability, glue quantity adjustable, cleaning easily.

Ø Creaser wheel adjustable, suit for 2-8mmthick paperboard.

Ø Imported quality rubber belt adopted, automatic folding. With paperboard rectify device and creasing rectify device.

V、Ejector & Counter unit

Ø Stacking and counting are simple and reliable.

Ø Digital control,operation easily and reliable. No-stop put in data and automatic counting.

Ø With rectification function.

Ø Paperboard counting and put out by pneumatic, atable and quickly.

List of the main electrical component:

Name | Brand |

Touch screen | Weinview (Taiwan) |

PLC | FATEK (Taiwan) |

Frequency converter | Schneider(France) |

Variable frequency motor | China |

Main bearing | NSK(Japan) |

Belt | China |

Button | Schneider(France) |

Contactor | Siemens(Germany) |

Relay switch | Omron (Japan) |

Travel switch | CHINT |

Breaker | CHINT |

Photo electricity | Omron (Japan) |

Switch power supply | Omron (Japan) |

Thermal overload relay | CHINT |

Gear motor | WANSHSIN(Taiwan ) |